In-Space Servicing, Assembly, and Manufacturing (ISAM) Robotics Reserach

NASA Goddard Space Flight Center

SAIC OSAM-1 Summer Intern (May - August 2022)

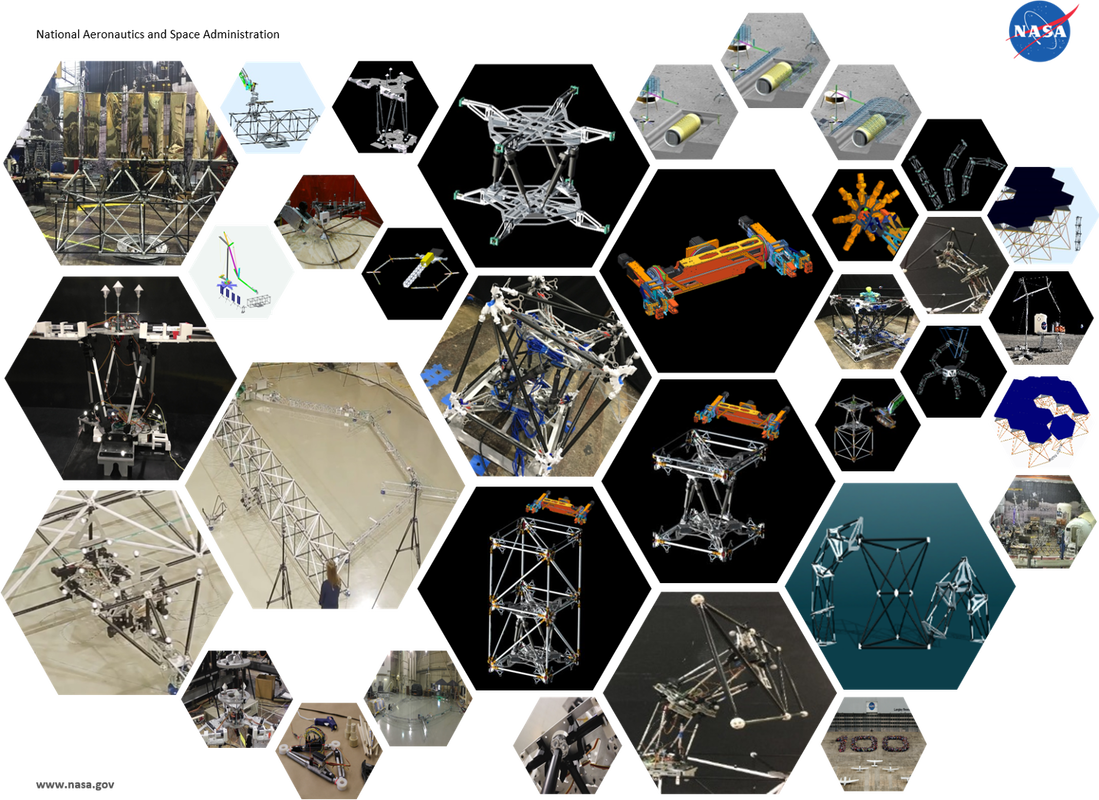

I spent the summer of 2022 interning at NASA Goddard Space Flight Center, working on some big picture stuff for In-Space Servicing, Assembly, and Manufacturing (ISAM)! Specifically doing an exhaustive literature review of ISAM space telescope concepts spanning 4 decades and 141 papers.

AIAA Space Automation and Robotics Technical Committee (SARTC)

Treasurer/Secretary (November 2021 - Present)

|

Executive team member for the AIAA technical committee responsible for writing the annual Aerospace America review article, recording meeting notes, and maintaining the committee’s budget.

|

U.S. Naval Research Laboratory

Internship - Naval Center for Space Technology, Robotics and Machine Learning Section (May 2021 - Present)

|

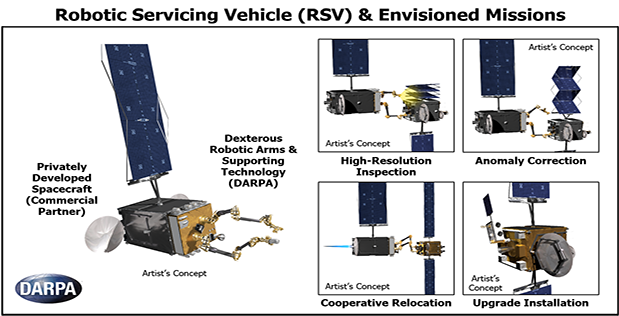

Robotic Servicing of Geosynchronous Satellites (RSGS)

At NRL I am developing a MATLAB data processing and plotting system for RSGS integration and testing. Aiding in operational testing of flight and engineering development robotics, including force torque sensor calibration and verification, compliance control, anomaly resolution, and functional checkout testing. Programing a KUKA industrial robot to perform repeated paths for visual servoing testing of a Marman ring to aid capture for rendezvous proximity operations (RPO). |

|

ROBOSAM LLC

Consulting (July 2020 - Spring 2023)

|

I founded a consulting company, ROBotic On-orbit Servicing, Assembly, and Manufacturing LLC (ROBOSAM LLC) in 2020 to work on more efforts like the iSAT Study (see below)! ROBOSAM is dedicated to promoting research in in-Space Servicing, Manufacturing, Assembly, Robotics, and Transportation (SMART) endeavors.

|

Space Servicing, Manufacturing, Assembly, Robotics, and Transportation (SMART)

Think Tank

|

I have been consulting as an organizer of the Space SMART Think Tank since it began in August 2020. This think tank is focused on answering the following questions: “What would the future of space look like with in-space SMART?”, “Why would it look like that?”, and “How do we get there?”

Check out the think tank's website: https://www.spacesmart.org/ |

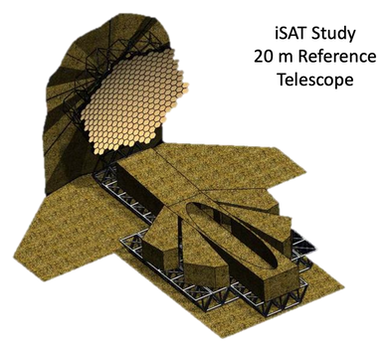

NASA in-Space Assembled Telescope (iSAT) Study

When is it advantageous to assemble space telescopes in space rather than to build them on the Earth and deploy them autonomously from individual launch vehicles?"

It was so exciting to be a member of this incredible study that submitted a white paper, about how in-space assembly could be used to build the next big space telescope, to the the National Academies’ 2020 Astronomy & Astrophysics Decadal Survey!

iSAT Study Website: https://exoplanets.nasa.gov/exep/technology/in-space-assembly/iSAT_study/

Final iSAT Study White Paper: https://exoplanets.nasa.gov/internal_resources/1254/

Scientific American Article about the Study: https://www.scientificamerican.com/article/finding-alien-life-may-require-giant-telescopes-built-in-orbit/

My responsibilities on the study included:

iSAT Study Website: https://exoplanets.nasa.gov/exep/technology/in-space-assembly/iSAT_study/

Final iSAT Study White Paper: https://exoplanets.nasa.gov/internal_resources/1254/

Scientific American Article about the Study: https://www.scientificamerican.com/article/finding-alien-life-may-require-giant-telescopes-built-in-orbit/

My responsibilities on the study included:

- Succinctly summarized weekly telecon and face to face meeting discussions and organized progress from subsystem teams (robotics, structures, optical, spacecraft, etc.) to assuring any requirements were conveyed between teams.

- Writing an over 200-page internal study report, collecting all the study findings, insights, and recommendations for the role of in-space assembly in future large space telescopes.

NASA Jet Propulsion Lab

Co-op - Robotic Vehicles and Manipulators Group (September - December 2019)

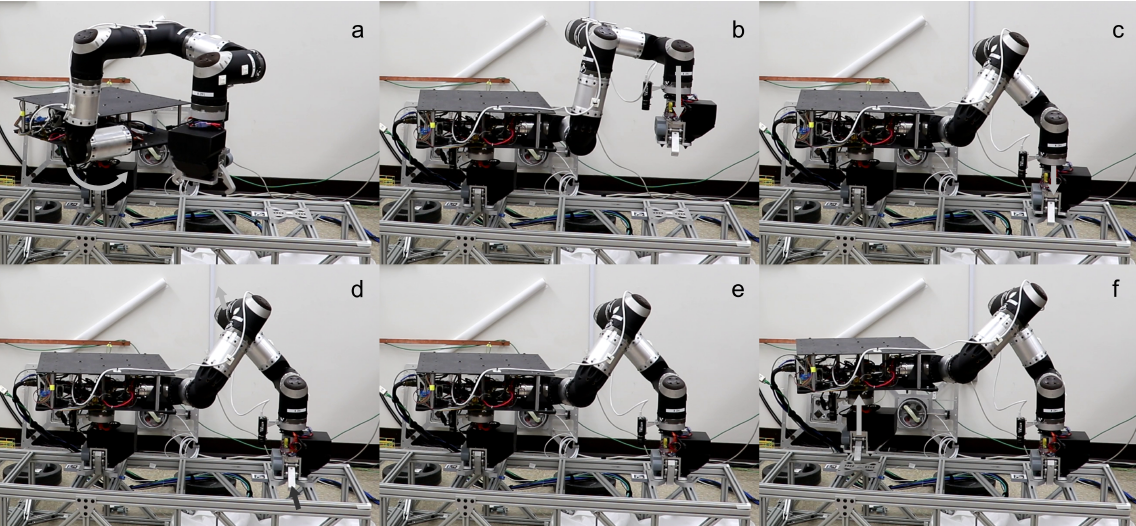

Persistent Robotically Operated Platform for Science (PROPS) - A.K.A. Technologies for International Science Space Station (TISSS)

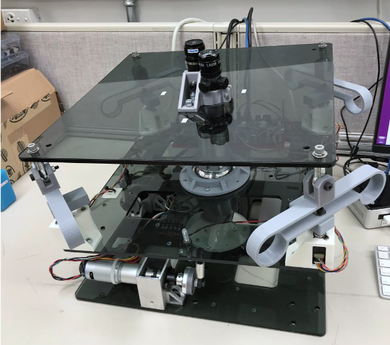

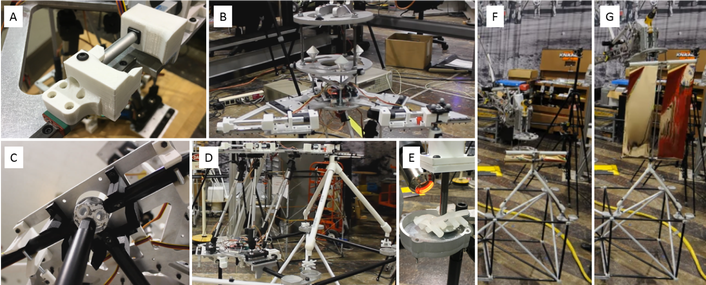

I created the controls system for an active precision pointing system, comprised of four linear actuators connecting the top and bottom plates of the pallet, to maintain instrument attitude within ± 3 millidegrees while counteracting disturbances under 1 Hz. I also conducted testing and created sequences for robotic arm maneuvers including end over end walking (shown below) and instrument manipulation.

I created the controls system for an active precision pointing system, comprised of four linear actuators connecting the top and bottom plates of the pallet, to maintain instrument attitude within ± 3 millidegrees while counteracting disturbances under 1 Hz. I also conducted testing and created sequences for robotic arm maneuvers including end over end walking (shown below) and instrument manipulation.

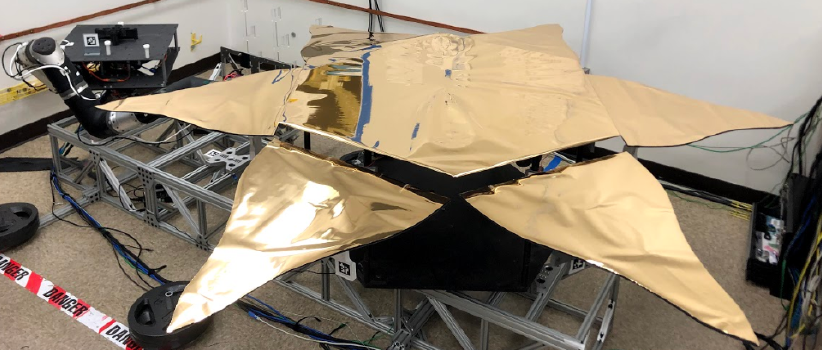

Starshade Analog Robotic Assembly Demonstration

In the final 2.5 weeks of my internship I proposed and lead a robotic demonstration of autonomous assembly of a 2.5-meter starshade mockup. I presented this work at the 2020 IROS Robotic In-Situ Servicing, Assembly, and Manufacturing (RISAM) Workshop.

Intern – Robotic Vehicles and Manipulators Group (June - August 2018)

Design and Testing of a Modular Satellite’s Pallet Hybrid Passive Isolation and Active Pointing System

With few exceptions, existing satellites are assembled on earth and launched into space with no provision for repairing defects or upgrading their capabilities, preventing them from evolving and dooming them to becoming space junk. JPL’s Robotic Vehicles and Manipulators group (347B) is working on a project called the Persistent Robotically Operated Platform for Science (PROPS) investigating how a satellite can be modularized into discrete components that can be assembled, reconfigured, or replaced as needed by an in development robotic system to realize the idea of a fully upgradable and serviceable satellite. The initial robot architecture uses a walking behavior as its main mobility mode which by iteratively attaching and detaching either end of the arm from designated docking points on the satellite it can move itself and carry satellite instrument pallets along the main bus. My research focused on designing the prototype pallet hybrid isolation system to connect a variety of interchangeable scientific payloads to the main satellite. The pallet system consists of passive flexures, used to mitigate high frequency motion, coupled with actuators, used for active pointing to compensate for low frequency motion/drift, to effetely keep instruments “still” despite disturbances from the satellite truss that they are mounted to.

With few exceptions, existing satellites are assembled on earth and launched into space with no provision for repairing defects or upgrading their capabilities, preventing them from evolving and dooming them to becoming space junk. JPL’s Robotic Vehicles and Manipulators group (347B) is working on a project called the Persistent Robotically Operated Platform for Science (PROPS) investigating how a satellite can be modularized into discrete components that can be assembled, reconfigured, or replaced as needed by an in development robotic system to realize the idea of a fully upgradable and serviceable satellite. The initial robot architecture uses a walking behavior as its main mobility mode which by iteratively attaching and detaching either end of the arm from designated docking points on the satellite it can move itself and carry satellite instrument pallets along the main bus. My research focused on designing the prototype pallet hybrid isolation system to connect a variety of interchangeable scientific payloads to the main satellite. The pallet system consists of passive flexures, used to mitigate high frequency motion, coupled with actuators, used for active pointing to compensate for low frequency motion/drift, to effetely keep instruments “still” despite disturbances from the satellite truss that they are mounted to.

NASA Langley Research Center

Intern – Robotic In-Space Assembly Research and Development (June - August 2019)

Highly Organized Multi-agent Enclosures (HOME)

I worked with 2 other interns to develop two soft robot modules that could change their shape, translate via rolling motion produced by sequential bladder inflation, join together, and rigidize into a final shape by cooling embedded thermoplastic.

I worked with 2 other interns to develop two soft robot modules that could change their shape, translate via rolling motion produced by sequential bladder inflation, join together, and rigidize into a final shape by cooling embedded thermoplastic.

|

|

|

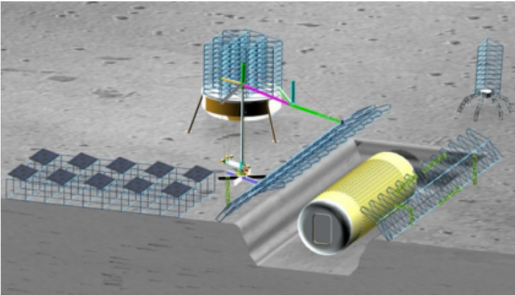

Lunar Crane, Lander Payload Manipulation, and Rover Changing Demonstration

I lead a team of 7 interns and contractors in completing a demonstration where a miniature version of the Lightweight Surface Manipulation System (LSMS-mini), small lunar crane, was mounted to the platform of a mock-lunar lander and performed tasks such as unloading payloads onto the back of a rover, swapping end effectors, charging the rover, and deploying ground solar panels.

I lead a team of 7 interns and contractors in completing a demonstration where a miniature version of the Lightweight Surface Manipulation System (LSMS-mini), small lunar crane, was mounted to the platform of a mock-lunar lander and performed tasks such as unloading payloads onto the back of a rover, swapping end effectors, charging the rover, and deploying ground solar panels.

Co-op – Robotic Assembly of Space Structures (May - December 2017)

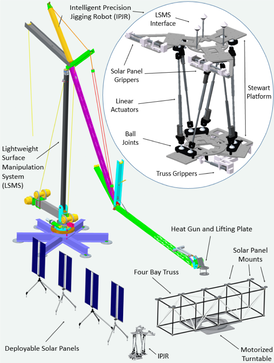

Commercial Infrastructure for Robotic Assembly and Servicing (CIRAS)

- Project Summary: NASA Langley Research Center (LaRC) was tasked by Orbital ATK to develop a high precision truss building robot for the CIRAS project and complete a demo.

- Challenges: The previous design of the NASA Intelligent Jigging and Assembly Robot (NINJAR) didn’t function properly so I re-designed it using Creo Parametric to create NINJAR 2.0.

- NINJAR required an immersive metrology system to allow for visual feedback - to achieve this I designed and fabricated four portable 2.5 meter tall, 2.5 meter wide panels, constructed with 80/20, and mounted VICON cameras and provide a reduced noise metrology setup.

- Results: Lead team of 8 other interns in building NINJAR 2.0 and conducting a successful demonstrations of its capabilities.

- First Test: It precisely positioned eight truss joints then team members attached struts between the joints to complete the truss bay. Precision of assembled truss was within 5-mm and 3-deg of the reference truss.

- Later Test: Conducted a tele-operated trial in which a truss bay was constructed by a team of three robots: NINJAR, the Strut Assembly, Manufacturing, Utility & Robotic Aid (SAMURAI), and the Lightweight Surface Manipulation System (LSMS). In this test team members operated the robots with controllers and succeeded in constructing a truss bay.

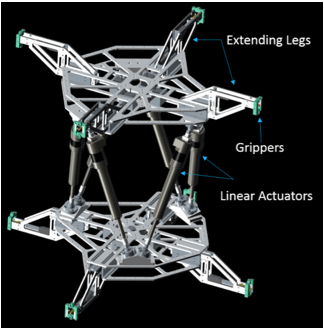

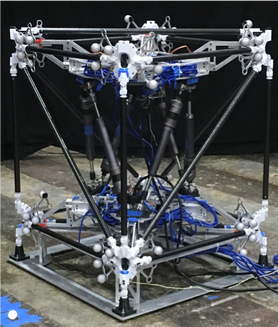

Assembly of Space SystEMs By using Locomotion and Error-correction for RobustnesS (ASSEMBLERS)

- Refined design to optimize Stewart platform robot to be lightweight, cut weight to a quarter of the previous versions and created the electronics system to run the ASSEMBLERS robots together.

- Lead team of interns and contractors in building two robots, each comprised of four Stewart platform units stacked.

- Project Summary: My mentor Erik Komendera was trying to win funding for his Early Career Initiative (ECI) concept called ASSEMBLERS. My role was to create renders for the proposal and produce prototype robots to demonstrate functionality as a proof of concept.

- Challenges: The application process was on a quick two month timeline so I had to design, make renders for in-space robotic assembly concepts using Creo Parametric, and prototype very quickly using a BCN3D Sigma 3D printer to fabricate parts and an Arduino to create an electronic control system controlled wirelessly via XBee modules.

- Results: Optimized Stewart platform robot: cut weight by 65% from previous designs.

- Lead team of interns in building two robots, each comprised of four Stewart platform units stacked on top of each other.

Intern – Robotic Assembly of Solar Array Modules by a Team of Robots (May - August 2016)

- Designed, built, and tested components for a teleoperated trial in which a team of robots, consisting of LSMS (a long reach manipulator) and an Intelligent Precision Jigging Robot (IPJR), assembled solar array modules onto a backbone truss.

- Rapidly prototyped Creo Parametric designs for the interfacing elements of the two robots, utilizing a MakerGear M2 3D printer and waterjet cutter to allow for quick iteration, maximizing verification time.

- Constructed and programmed electronic infrastructure, Arduino hardware/software, required for teleoperation.

Photo Sources:

[1] https://www.darpa.mil/program/robotic-servicing-of-geosynchronous-satellites

[2] https://exoplanets.nasa.gov/internal_resources/1081/

[3] https://exoplanets.nasa.gov/system/internal_resources/details/original/967_LRC-2018-B701_P-02711.jpg

[4] R. Mukherjee et al., "A Robotically Assembled and Serviced Science Station for Earth Observations," 2020 IEEE Aerospace Conference, Big Sky, MT, USA, 2020, pp. 1-15, doi:10.1109/AERO47225.2020.9172368.

[5] S. Glassner, G. Raiola, R. Mukherjee, S. Backus, A. Brinkman, T. Setterfield, 2020. Starshade Analog Robotic Assembly Demonstration. Robotic In-Situ Manufacturing, Structural Assembly and Servicing (RISMSAS) ICRA 2020 Workshop

[6] https://www-robotics.jpl.nasa.gov/tasks/showTask.cfm?FuseAction=ShowTask&TaskID=313&tdaID=700113

[7] Iok Wong, William Chapin, and Erik E. Komendera. "Validation of Operations for the In-Space Assembly of a Backbone Truss for a Solar-Electric Propulsion Tug", 2018 AIAA SPACE and Astronautics Forum and Exposition, AIAA SPACE Forum, (AIAA 2018-5228) https://doi.org/10.2514/6.2018-5228

[8] https://www.nasa.gov/mission_pages/tdm/irma/orbital-atk-supports-ground-testing-on-ciras-at-nasa-s-langley-research-center.html

[9] http://ek2.co/

[10] Komendera, E.E., Adhikari, S., Glassner, S., Kishen, A., and Quartaro, A., 2017. Structure Assembly by a Heterogeneous Team of Robots Using State Estimation, Generalized Joints, and Mobile Parallel Manipulators. In IEEE/RSJ Conference on Intelligent Robots and Systems (p. TBD), Vancouver, BC.

[1] https://www.darpa.mil/program/robotic-servicing-of-geosynchronous-satellites

[2] https://exoplanets.nasa.gov/internal_resources/1081/

[3] https://exoplanets.nasa.gov/system/internal_resources/details/original/967_LRC-2018-B701_P-02711.jpg

[4] R. Mukherjee et al., "A Robotically Assembled and Serviced Science Station for Earth Observations," 2020 IEEE Aerospace Conference, Big Sky, MT, USA, 2020, pp. 1-15, doi:10.1109/AERO47225.2020.9172368.

[5] S. Glassner, G. Raiola, R. Mukherjee, S. Backus, A. Brinkman, T. Setterfield, 2020. Starshade Analog Robotic Assembly Demonstration. Robotic In-Situ Manufacturing, Structural Assembly and Servicing (RISMSAS) ICRA 2020 Workshop

[6] https://www-robotics.jpl.nasa.gov/tasks/showTask.cfm?FuseAction=ShowTask&TaskID=313&tdaID=700113

[7] Iok Wong, William Chapin, and Erik E. Komendera. "Validation of Operations for the In-Space Assembly of a Backbone Truss for a Solar-Electric Propulsion Tug", 2018 AIAA SPACE and Astronautics Forum and Exposition, AIAA SPACE Forum, (AIAA 2018-5228) https://doi.org/10.2514/6.2018-5228

[8] https://www.nasa.gov/mission_pages/tdm/irma/orbital-atk-supports-ground-testing-on-ciras-at-nasa-s-langley-research-center.html

[9] http://ek2.co/

[10] Komendera, E.E., Adhikari, S., Glassner, S., Kishen, A., and Quartaro, A., 2017. Structure Assembly by a Heterogeneous Team of Robots Using State Estimation, Generalized Joints, and Mobile Parallel Manipulators. In IEEE/RSJ Conference on Intelligent Robots and Systems (p. TBD), Vancouver, BC.